You can easily find the product that suits you here.

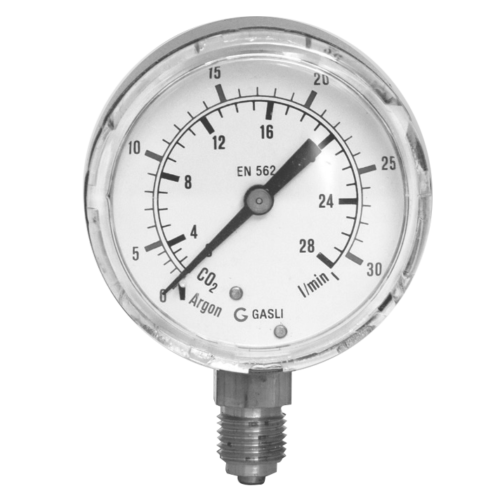

Pressure gauges specials

Are you looking for a specific pressure gauge? In the product range of EMVO Techniek you will find various specials. You can think of, for example, stainless steel gauges, differential manometers, pressure recorders and deep sea manometers. Simply request a quote by contacting us. Do you have a question? Do you wish appropriate advice? We are happy to help.

Stainless steel gauges

These special gauges are perfect for use in corrosive environments and meant for measuring both gas and liquid. Stainless steel is an alloy of iron and carbon to which a small amount of chromium is added. The chromium in the alloy increases corrosion resistance of the significantly. The chromium forms a thin, oxygen proof layer on the steel, preventing it from rusting.

read more...

Differential manometers

A differential manometer is meant for measuring differential pressure in two separate pressure systems. To that end, the dispose of two connections: one for high, and one for low pressure.

Pressure recorders

Pressure recorders are used for recording variable pressure data. Because of its traditional character, its barely susceptible to fraud. An inspector can sign directly on the recording chart. Information in a digital archive is more susceptible to fraud and could be adapted theoretically, which is the reason that some consultancy firms do not accept digital data. Our pressure recorders are high quality and easy to use. It is possible to make 24-hour recordings as well as 7 day rotations.

Deep sea manometers

Our deep sea manometers are resistant under water up to 4000 meters. We have a variety of deep sea pressure gauges in stock.

Your wholesaler for manometers

As a wholesaler, EMVO Techniek has been focussing on gauges, thermometers and pressure transmitters since 1982. Nowadays, through our long years of experience, we can present our customers a complete product range of pressure gauges. Also gauges in several variants: gauges specials. View the extensive possibilities in our webshop at your leisure and request a quote. Please contact us for appropriate advice.